Reflective Road Studs Detection

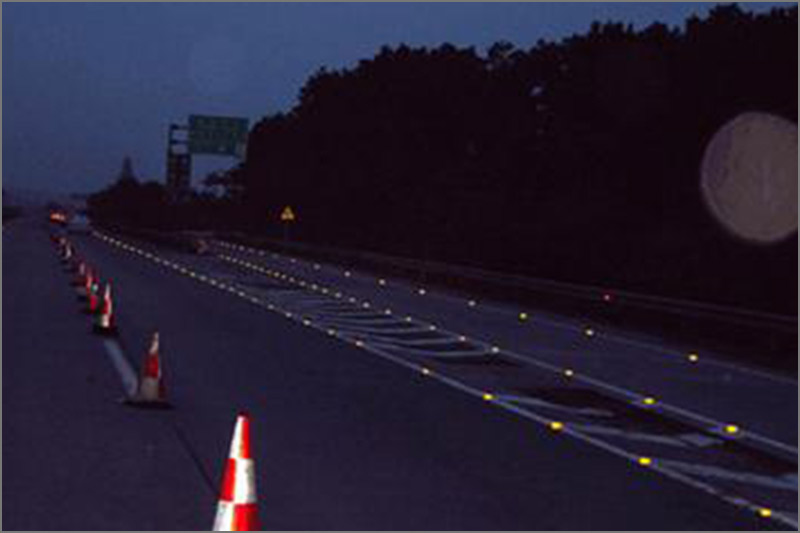

Road stud, especially solar led road stud is famous for its quality and long life span. As we all know, a qualified reflective road stud can work for several years even more than ten years. But the unqualified reflective road studs would be destroyed for a short time, lasting for only months.

Therefore, the quality of reflective road stud is very important. How can we test the quality of a reflective road stud?

In the United States, the applicable standard for road stud is ASTM 4280. We have made reference to ASTM4280 to a great extent when formulating the reflective road stud standard, and in some provisions, we still need to exceed the American Standard.

For example, due to the serious overloading of Chinese vehicles, the requirements for the compression resistance of reflective road studs have exceeded the American standards; moreover, the revision of domestic reflective road stud standards keeps pace with the times and basically achieves the practical and realistic requirements standards are not important.

Since there is no problem with the reflective road stud detection method of the reflective road stud, it is necessary to pay attention to the detection method. China’s detection methods are probably these. For sample testing, i.e. only responsible for samples. Due to the failure of mass inspection of all reflective road stud products, uneven quality of reflective road stud products may occur.

The second method of reflective road stud detection is batch inspection, that is, only responsible for the quality of this batch of goods. The third way of reflective road stud detection is to inspect the factory to find out whether there are machines and equipment, whether there is a perfect system, and to issue a batch production license.